Related Resources: weld

Welded Joint Efficiency Table Recommendations

Structural Design and Analysis

Pressure Vessel Design and Engineering

Welded joint efficiency table recommendations

Weld Joints and their general efficiency (recommendation, consult ASME pressure vessel code or similar application standards when required).

1.0 = 100%, 0.85 = 85% efficiency.

Joint efficiency is concept found in several API and ASME codes. It is a numerical value, which represents a percentage, expressed as the ratio of the strength of a riveted, welded, or brazed joint to the strength of the base material. It is also a way to introduce safety factors in welding of shells for containment, and can be expressed as follows: Joint Efficiency = Strength of weld/Strength of base material. In other standards, values for Joint Efficiency in welds are assumed according to 2 traits: Type of welded joint and extent of NDE required for the welded joint. Joint efficiency varies with weld type.

|

Types of Weld

|

Joint Efficiency, E

|

|||

|

Full

Inspection Required |

Spot

Inspected |

Not Inspected

|

||

|

Butt joint as attained by double-welding or by other means which will obtain the same quality of deposited weld material on the outside weld surface. If a backing strip is used it should be remove after completion of welding. |

1.00

|

0.85

|

0.70

|

|

Single welded butt joint with backing strip which remains in place after welding

|

0.90

|

0.80

|

0.65

|

|

Single welded butt joint without use of backing strip

|

-

|

-

|

0.60

|

|

|

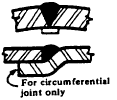

Double full fillet lap joint

|

-

|

-

|

0.55

|

|

Single full fillet lap joint with plug welds

|

-

|

-

|

0.50

|

|

Single full fillet lap joint without plug welds

|

-

|

-

|

0.45

|