Related Resources: motors

Stepper Motor Size Dimensions Table

Power Transmission

Electric Motors and Driver Review

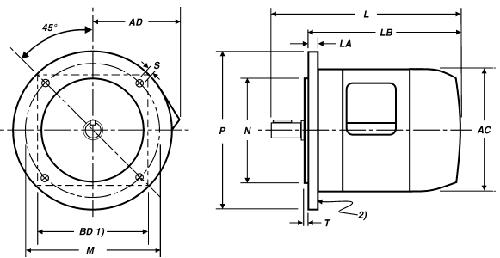

Stepper Control Motors Size and Dimensions Table Inch Units Round and Square Motors. For sizes NEMA Flange 17 to 56.

Note: This document annotates dimensional data specified by NEMA standard (see bottom of webpage). Many industry stepping motor manufacturers have chosen to deviate from this industry standard. For example, NEMA 17 Stepping motor typically utilize an M3 vs a 4-10unc thread for the tapped holes in the mounting flange. Therefore, this dimensional data should be used as a guide and stepping motor dimensional and tolerance conformance for be verified.

Dimensions for mounting flanges for inch dimension motors

|

Flange

number |

M

inches (Bolt Circle) or Diagonal Distance |

N

|

P

Maximum inches |

BD c

inches |

Number

of holes |

||

|

Nominal

|

Tolerance

|

||||||

|

inches

|

inches

|

inches

|

|||||

|

17

|

1.725a

|

0.8661

|

0

|

-0.0020

|

2.36

|

1.7

|

4

|

|

23

|

2.625

|

1.5000

|

0

|

-0.0020

|

3.21

|

2.3

|

4

|

|

34

|

3.875

|

2.8750

|

0

|

-0.0020

|

3.58

|

3.4

|

4

|

|

42

|

4.950

|

2.1875

|

0

|

-0.0020

|

6.19

|

4.2

|

4

|

|

48

|

3.750

|

3.0000

|

0

|

-0.0030

|

5.63

|

—

|

4

|

|---|---|---|---|---|---|---|---|

|

56

|

5.875

|

4.5000

|

0

|

-0.0030

|

8.00b

|

—

|

4

|

|

Flange

Number |

S

Free holes (for D flange) |

Tapped holes

(for C flange) thread |

T

|

|||

|

Nominal

inches |

Tolerance

|

Maximum

inches |

Minimum

inches |

|||

|

inches

|

inches

|

|||||

|

17

|

0.150

|

+0.010

|

-0.010

|

4-40

|

0.09

|

0.03

|

|

23

|

0.205

|

+0.010

|

-0.010

|

8-32

|

0.13

|

0.06

|

|

34

|

0.220

|

+0.010

|

-0.010

|

10-32

|

0.13

|

0.06

|

|

42

|

0.280

|

+0.010

|

-0.010

|

0.250-20

|

0.13

|

0.06

|

|

48

|

0.280

|

+0.010

|

-0.010

|

0.250-20

|

0.16

|

0.10

|

|

56

|

0.400

|

+0.010

|

-0.010

|

0.375-16

|

0.16

|

0.10

|

a 1.725 applies to C flange (threaded holes). For D flange (free holes), dimension is 2.000.

For rectangular (square) hole center line dimensions see: Bolt Circle Coordinate Calculator

example calculation:

NEMA 17, Bolt circle = dia. 1.75, starting angle 45 deg, No. holes: 4

From center of flange, x = 0.610, y = 0.610 or hole to hole x (left to right) = .610 x 2 = 1.220, hole to hole y (bottom to upper) .610 x 2 = 1.220

b The standard nominal P dimension is 6.50 inches for flange number 56.

c BD dimensions shown (for non-circular flanges) are approximate values for reference only. An actual BD value is determined by the manufacturer. For square flanges, the BD value chosen by the manufacturer may require rounding of the quare flange corners to fit within the P maximum diametervalues shown.

Length (Dimesion) Conversions

Equations:

inches x 25.4 = mm

mm / 25.4 = inches

References:

NEMA ICS 16 Standard, Table 4 "Dimensions for mounting flanges for inch dimension motors"

INDUSTRIAL CONTROL AND SYSTEMS

MOTION/POSITION CONTROL MOTORS, CONTROLS, AND FEEDBACK DEVICES