Related Resources: motors

Rated Shaft Loading of DC Motors

Electric Motors, Generators and Drives

Application of Overhung Loads to Electric Motor Shafts

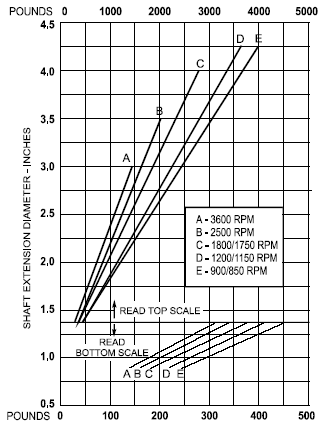

The image below shows minimum design limits for overhung loads for dc motors, designation A, B, C, D and E having shaft extensions designated by the frame subscript AT. These limits should not be exceeded. Bearing and shaft failure constitute a safety hazard and safeguards suitable to each application should be taken. limits for loads applied at the end of the shaft and at the center of the N-W dimension. In general, the closer the load is applied to the motor bearing the less will be the load on the bearing and the greater the assurance of trouble-free service. The center of the load should not be beyond the end of the shaft.

In the case of a sheave or pulley, the inner edge should not be closer to the bearing than the shoulder on the shaft but should be as close to this point as possible. In the case of chain sprocket or gears, the outer edge of the sprocket or gear should not extend beyond the end of the motor shaft. Applications which result in a thrust or axial component of load such as helical gears are also not covered.

Rated Shaft Loading of DC Motors "AT" Frame Designation that Have Radial Overhung Load at End of Shaft

NOTES

1 For load at center of N-W dimensions add 10%.

2 For intermediate speeds interpolate between curves.

3 ATS shafts are excluded. Consult manufacturer for load capabilities.