Related Resources: motors

Metric Stepper Motor Shafts Size Data Table

Power Transmission

Electric Motors and Driver Review

Table of dimensions for shafts, keys and keyways for metric dimension Stepper motors

Note: This document annotates dimensional data specified by NEMA standard (see bottom of webpage). Many industry stepping motor manufacturers have chosen to deviate from this industry standard.

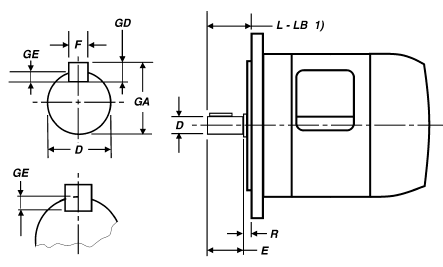

Legend

1) L minus LB (L-LB) is the preferred designation for the length of the shaft from the mounting surface of the flange. Dimension L-LB can be determined from dimension E+R included in the tables (L-LB = E+R).

Stepper Motor shafts, keys and keyways dimensions for metric size table.

|

D

|

E

Nom. mm |

R

mm |

Key

|

Keyway

|

Max.

Cont. Shaft Torque N-m |

||||||||||||

|

F

|

GD

|

F

|

GE

|

||||||||||||||

|

Nom.

mm |

Tolb

|

Nom.

mm |

Tol.

|

Nom.

mm |

Tol.

|

Nom.

mm |

Tol.

|

Nom.

mm |

Tol.

|

||||||||

|

µm

|

µm

|

µm

|

µm

|

µm

|

µm

|

µm

|

µm

|

µm

|

µm

|

||||||||

|

5

|

+0

|

-8

|

16

|

0

|

a

|

||||||||||||

|

6

|

+0

|

-8

|

16

|

0

|

|||||||||||||

|

7

|

0

|

-9

|

16

|

0

|

2

|

0

|

-25

|

2

|

0

|

-25

|

2

|

-4

|

-29

|

1.2

|

100

|

0

|

0.25

|

|

8

|

0

|

-9

|

18

|

0

|

2

|

0

|

-25

|

2

|

0

|

-25

|

2

|

-4

|

-29

|

1.2

|

100

|

0

|

0.4

|

|

9

|

0

|

-9

|

20

|

0

|

3

|

0

|

-25

|

3

|

0

|

-25

|

3

|

-4

|

-29

|

1.8

|

100

|

0

|

0.63

|

|

10

|

0

|

-9

|

20

|

12

|

3

|

0

|

-25

|

3

|

0

|

-25

|

3

|

-4

|

-29

|

1.8

|

100

|

0

|

0.875

|

|

11

|

0

|

-11

|

23

|

0

|

4

|

0

|

-30

|

4

|

0

|

-30

|

4

|

0

|

-30

|

2.5

|

100

|

0

|

1.25

|

|

14

|

0

|

-11

|

30

|

0

|

5

|

0

|

-30

|

5

|

0

|

-30

|

5

|

0

|

-30

|

3

|

100

|

0

|

2.8

|

|

16

|

0

|

-11

|

40

|

0

|

5

|

0

|

-30

|

5

|

0

|

-30

|

5

|

0

|

-30

|

3

|

100

|

0

|

4.1

|

|

18

|

0

|

-11

|

40

|

0

|

6

|

0

|

-30

|

6

|

0

|

-30

|

6

|

0

|

-30

|

3.5

|

100

|

0

|

7.1

|

|

19

|

0

|

-13

|

40

|

0

|

6

|

0

|

-30

|

6

|

0

|

-30

|

6

|

0

|

-30

|

3.5

|

100

|

0

|

8.25

|

|

22

|

0

|

-13

|

50

|

0

|

6

|

0

|

-30

|

6

|

0

|

-30

|

6

|

0

|

-30

|

3.5

|

100

|

0

|

14

|

|

24

|

0

|

-13

|

50

|

0

|

8

|

0

|

-36

|

7

|

0

|

-90

|

8

|

0

|

-36

|

4

|

200

|

0

|

18

|

|

28

|

0

|

-13

|

60

|

0

|

8

|

0

|

-36

|

7

|

0

|

-90

|

8

|

0

|

-36

|

4

|

200

|

0

|

31.5

|

|

32

|

0

|

-16

|

80

|

0

|

10

|

0

|

-36

|

8

|

0

|

-90

|

10

|

0

|

-36

|

5

|

200

|

0

|

50

|

|

35

|

0

|

-16

|

76

|

3

|

10

|

0

|

-36

|

8

|

0

|

-90

|

10

|

0

|

-36

|

5

|

300

|

0

|

69

|

|

38

|

0

|

-16

|

80

|

0

|

10

|

0

|

-36

|

8

|

0

|

-90

|

10

|

0

|

-36

|

5

|

200

|

0

|

90

|

|

42

|

0

|

-16

|

110

|

0

|

12

|

0

|

-43

|

8

|

0

|

-90

|

12

|

0

|

-43

|

5

|

200

|

0

|

125

|

|

48

|

0

|

-16

|

110

|

0

|

14

|

0

|

-43

|

9

|

0

|

-90

|

14

|

0

|

-43

|

5.5

|

200

|

0

|

200

|

|

55

|

0

|

-41

|

110

|

0

|

16

|

0

|

-43

|

10

|

0

|

-90

|

16

|

0

|

-43

|

6

|

200

|

0

|

355

|

|

60

|

0

|

-41

|

140

|

0

|

18

|

0

|

-43

|

11

|

0

|

-110

|

18

|

0

|

-43

|

7

|

200

|

0

|

450

|

|

65

|

0

|

-41

|

140

|

0

|

18

|

0

|

-43

|

11

|

0

|

-110

|

18

|

0

|

-43

|

7

|

200

|

0

|

630

|

|

70

|

0

|

-41

|

140

|

0

|

20

|

0

|

-52

|

12

|

0

|

-110

|

20

|

0

|

-52

|

7.5

|

200

|

0

|

800

|

|

75

|

0

|

-41

|

140

|

0

|

20

|

0

|

-52

|

12

|

0

|

-110

|

20

|

0

|

-52

|

7.5

|

200

|

0

|

1000

|

|

80

|

0

|

-41

|

170

|

0

|

22

|

0

|

-52

|

14

|

0

|

-110

|

22

|

0

|

-52

|

9

|

200

|

0

|

1250

|

|

85

|

0

|

-48

|

170

|

0

|

22

|

0

|

-52

|

14

|

0

|

-110

|

22

|

0

|

-52

|

9

|

200

|

0

|

1600

|

|

90

|

0

|

-48

|

170

|

0

|

25

|

0

|

-52

|

14

|

0

|

-110

|

25

|

0

|

-52

|

9

|

200

|

0

|

1900

|

a The key and keyway is not provided for shaft numbers 5 and 6.

b Tolerances follow North American practice; alternate tolerancing is provided in IEC 60072-1.

Reference: NEMA ICS 16 Standard