Related Resources: calculators

Retaining Snap Ring Stress and Failure Formulas and Calculator

ANSI Hardware Guide

Metric Engineering Hardware Guide

Retaining Snap Ring Stress and Failure Formulas and Calculator

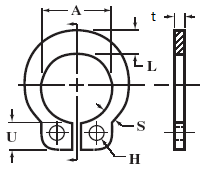

Failure of a retaining snap ring application can result from failure of the ring itself, failure of the groove, or both. If a ring fails, the cause is likely to be from shearing of the ring. Shear failure occurs when a ring is installed in a groove and loaded by a retained part with both the groove and the retained part having a compressive yield strength greater than 45,000 psi (310 MPa); or when the load is applied through a retained part and groove, both having sharp corners and line-to-line contact; or when the ring is too thin in section compared with its diameter.

Ps = ( π D t Ss ) / K

Where:

Ps = Thrust force ( lbf, N ),

D = Shaft or housing diameter (in, mm),

t = Retaining ring thickness (in, mm),

Ss = Shear strength of the retaining ring material (lb/in2, N/mm2)

K = Factor of safety

Related:

- Retaining Rings Types and Applications

- Centrifugal Capacity Retaining Snap Rings

- Internal Retaining Snap Ring Sizes and Groove Design Chart

- Internal Retaining Snap Ring Sizes and Groove Design Bore Sizes 3.062 - 5.000

- Internal Retaining Snap Ring Sizes and Groove Design Chart Sizes 5.250 - 8.250

- Internal Retaining Snap Ring Sizes and Groove Design sizes 1.562 to 3.000

- Metric Tapered Retaining Snap Rings Size Chart

References:

Machinery's Handbook, 30th edition