Related Resources: calculators

Pipe and Compression Coupling Tolerance Analysis Equations and Calculators

Mechanical Tolerance Analysis Equation and Calculators

Pipe and Compression Coupling Tolerance Analysis Equations and Calculators

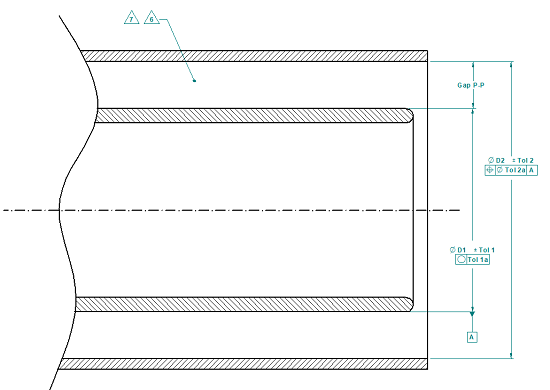

This engineering design calculator and related formulas will determine the nominal, maximum and minimum coupling gap.

Preview: Pipe and Compression Coupling Tolerance Analysis Calculators

Maximum Nominal Gap P-P = [ ( D2 + Tol 2 ) - ( D1 - Tol 1 ) ] / 2

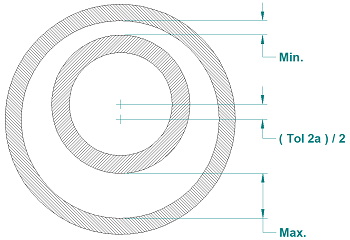

Max Gap P-P = Maximum Nominal Gap P-P + Tol 2a/2

Min. Gap P-P = Maximum Nominal Gap P-P - Tol 2a/2

Minimum Nominal Gap P-P = [ ( D2 - Tol 2 ) - ( D1 + Tol 1 ) ] / 2

Max Gap P-P = Minimum Nominal Gap P-P + Tol 2a/2

Min. Gap P-P = Minimum Nominal Gap P-P - Tol 2a/2

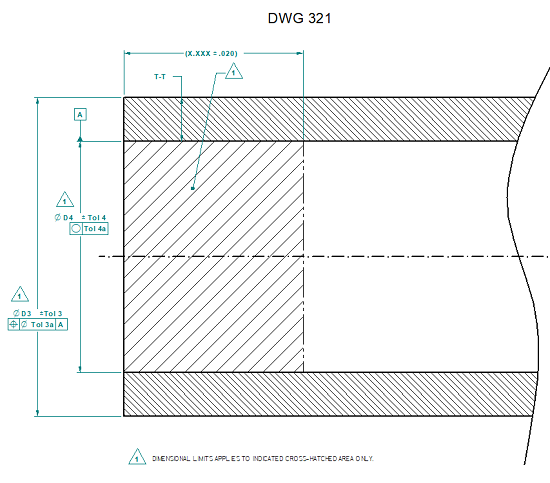

1) This engineering design calculator and related formulas will determine the nominal, maximum and minimum wall thickness of a pipe.

Maximum Nominal Thickness T-T = [ ( D3 + Tol 3 ) - ( D4 - Tol 4 ) ] / 2

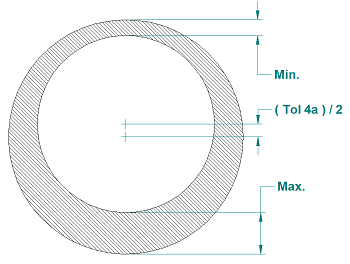

Max Wall Thickness = Maximum Nominal Thickness T-T + Tol 3a/2

Min. Wall Thickness = Maximum Nominal Thickness T-T - Tol 3a/2

Minimum Nominal Thickness T-T = [ ( D3 - Tol 3 ) + ( D4 + Tol 4 ) ] / 2

Max Wall Thickness = Minimum Nominal Gap T-T + ( Tol 3a ) / 2

Min. Wall Thickness = Minimum Nominal Gap T-T - ( Tol 3a ) / 2

Author: Kelly Bramble, Engineers Edge

Related eferences: ASME Y14.5-2018, ASME Y14.5-2009, ISO 1101 2017